Advantages of using Toroidal Transformer

Worth Investing.....

The toroidal transformer has a lot of advantages when compared with the EI kind:

Toroidal transformers could be more compact than traditional power transformers of the very same ratings.. Toroidal cores allow for 100 percent of their core to be wound and used up, whereas other core contours always have segments that have to reach around the windings to produce the return magnetic route. These segments add declines and weight, which is not the case with toroidal cores.

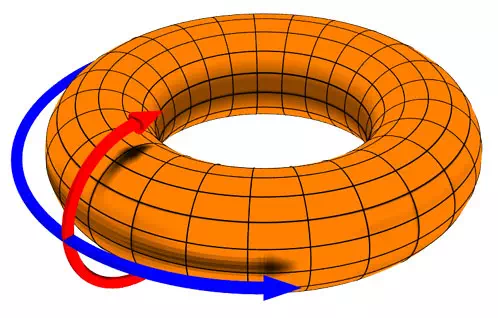

Employing a toroidal, or doughnut-shaped core allows a decrease in the dimensions and weight of a transformer by 20% to 50 percent compared with traditional cores with-out sacrificing functionality. That is possible because core losses in toroids are generally 10 percent to 20 percent of their entire energy loss, together with the rest dropped in the windings. Toroids are deployed in low and high voltage transformers, in which small losses are critical. When comparing with traditional transformers at which the core losses complete 50 percent of their entire energy reduction, the benefits are visible.

Employing the large permeability and low-loss qualities of a contemporary transformer core has broadened the toroidal transformer design skills. With advanced methods and equipment, the toroidal transformer not only offers many performance benefits, but it's also an inexpensive solution to contemporary demands. That is because the form of this transformer requires the smallest amount of space. The windings are spread over the core, thus producing the cable length limited. This size makes it useful in tiny products that are compact. The compact dimensions of toroidal transformers make them ideally suited to applications in digital circuits. Therefore these transformers are usually utilized in computers, inverters, plus a large number of similar apparatus.

Lightweight core -- The core of a toroidal transformer weighs significantly less than usual transformers because of its raw materials. As much as 50% savings (more when utilized with a lid and bolt or screw ). The toroidal core gets the shape for creating a transformer using the quantity of material. All of the windings over the whole circumference of the core, which makes the cable length brief. This setup causes lower twisting efficacy and resistance. A greater flux-density is potential as the magnetic flux is at precisely the same way as the rolling direction of this silicon-steel core.

Excellent Temperature Control Cooler operating temperatures and low magnetizing present are just two of the advantages.A higher current density may be used, as the whole surface of the toroidal core allows efficient cooling of the aluminium windings. The iron losses are extremely small; generally 1.1 Watts/Kg in 1.7 Tesla and 50 Hertz - providing quite little magnetizing current, which leads to the superb temperature evaluation of this toroidal transformer. The form of this transformer requires substance and the windings over the core, which makes the cable length shorter than in other transformers. This efficiency could translate to lower temperatures

Volume reduction Space savings up to 50 percent when provided with mounting brackets and terminal blocks to get a drop-in laminate replacement as well as 64 percent when equipped with flying leads rather than terminal blocks.

Adaptive Dimensions Though the cross-section of a toroidal transformer is kept constant, the diameter and height could be changed to accommodate the program. We can Install Toroidal transformers in applications where other transformers can't. Toroidal transformers require just one centre bolt to be mounted. The process becomes faster and more easy for transformers, thus reducing assembly time by equipment makers. We can mount Toroidal transformers with the assistance of pressure-less mounting plates, resin centre potting with metal inserts, PCB mounting, or total encapsulation in metal or plastic housings. Mounted Toroidal transformers could be achieved with a twist because of that the connection period reduces. This process reduces maintenance, fix and replacement-related downtime. An individual can also use different mounting options such as using enclosures or instance it into a plastic container. Mounting Toroidal transformers can be achieved in a brief moment Using only one twist. This advantage helps downtime and restricts maintenance.

High performance - Less Stray Magnetic Field Virtually Ideal Magnetic Circuit Combining these components result gaps because of that stray magnetic field appears. Whereas from the toroidal transformer, there's absolutely no such air gap, therefore these emit an remarkably faint magnetic interference field. The hum increases since at start then drops over time. Reaching low levels of stray field is a significant factor for your equipment designer since the occurrence can create unwanted sound through interference with sensitive electronic equipment. A toroidal transformer will normally offer you a reduction in 8:1 in magnetic interference amounts compare with conventional frame style laminate kinds. The symmetry of this toroidal form makes sure the quantity of magnetic flux that flows away from the core is low, which leads to more efficiency. These small-sized toroidal transformers are employed in many different electrical circuits of amplifiers, inverters and power supplies to be utilized in electrical equipment such as TVs, radios, sound systems, and computers.

Negligible Physical Vibration However, the building of toroidal transformers helps dampen acoustic sound. The uniform twisting of this core leaves no air openings, thus leaving no loose sheets to vibrate, finally leading to lower hum. Hum heard while the power switches on reduce dramatically in seconds. Further enhanced stability from the aluminium windings which closely encircle the whole circumference of the core dampens the rest. With many clients in the Audio industry, we have developed expert design and production methods to offer the quietest transformers possible.With almost no drawbacks, such as greater losses, and bigger measurements. The core of a traditional transformer is shaped by 2 different sections of piled steel sheets. These components have loose sheet finishes which cause the transformer to vibrate leading to creating a disturbing hum. On the other hand, the core of a toroidal transformer is composed of a very long strip of steel that's closely wound to provide it with a toroidal form. Consequently, it leads to a nearly hum-less transformer. The windings tightly enveloping the core and also the lack of this air gap efficiently decrease magnetostriction, that's the most important supply of mechanical degradation utilized in other transformers. The air gap lack provides 8:1 loss of sensory sound, which explains the reason why toroidal transformers are quiet. This behaviour makes these transformers the sound equipment to be utilized in hospitals and workplace surroundings in which the annoying hum isn't acceptable. Well-constructed toroids don't have any limit for their windings, meaning there is not any physical difference between the beginning and end of the twisting to allow radiated ramble fields. They also have high immunity to some outside magnetic fields levied upon them.The field produced by magnetization also referred to as the stray field, is lower at a toroidal transformer, on account of the uniform core windings. Less magnetic disturbance in toroids contributes to greater performance. An E-I, or laminate, the transformer is made up of a set of coils wrapped around frame cores, placed close together and sealed within an enclosure. Layered on top of each other, It isn't important whether the wires touch physically. Toroidal fields are more streamlined compared to fields in a laminate transformer; therefore, there's less magnetic power to interfere with sensitive circuit elements. Producers love Toroidal transformers because When used in sound equipment, it makes less hum and distortion compared to laminate ones. Roughly 85-95percent lower than traditional laminated transformers.

Toroidal transformers are used in place of transformers because of many different motives, some of which are stated below.

Dimensions and Weight of Toroidal transformers are nearly half the size and weight of regular transformers. It's the efficiency that saves around 50 percent of dimensions and weight. This property simplifies the layout of cupboards, mounting mechanical and configuration geometry; hence making it helpful for small and much more streamlined electric products. Additionally, the diameter-to-height ratio of a toroid is readily altered to match the mechanical layout, making it good for low profile equipment. This creates toroidal transformers exceptionally acceptable for applications in electronics equipment like medical equipment and low-level amplifiers. Low excitation electricity: It requires very little energy to keep the magnetic field in a toroidal core, which can be called excitation or quiescent power. Toroids require just 1/16th of the excitation energy of other transformers, so 1/16th the power demanded by other transformers in standby mode. This low power usage causes big savings in big transformer applications like controls. This simplicity of mounting reduces meeting time and accelerate production time, lowering the components count of mounting hardware. Flexible measurements With continuous cross-section, the diameter, and height of toroidal transformers may be changed to suit virtually any application. Aside from the benefits mentioned previously, these transformers integrated and can be customized with the features to gain any application. You can rely on us, the quality manufacturer of toroidal transformer in India to supply you with personalized transformers to fit your program kind to the fullest.

Cons: Toroids have a few disadvantages for Manufacturers and Assemblers. They are more difficult to build and to complete. Special equipment needed to wind the transformer. The bolt shouldn't be over-tightened to avoid harming the windings. The two ends of the bolt should not be allowed to concurrently develop in contact with the metal chassis because this would function as a shorted turn.