Testing Toroidal Transformer

Understanding the Readings.....

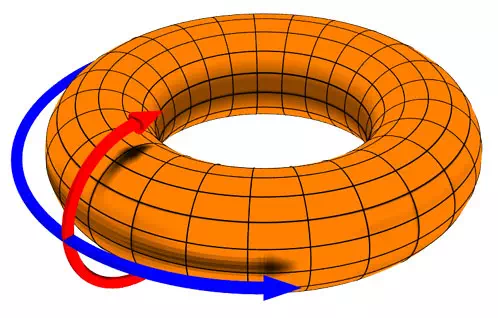

The main principle on which transformers work is that every electrical field creates a magnetic field and every magnetic field generates an electrical discipline. There are various kinds of transformers available in the market today. If you'd like the transformers, you can get in contact with us, that supplies the power transformers in India is a EI transformer maker in India. Whatever sort of transformer, it is crucial to test it to know that it operates. First of all, you want to inspect the transformer visually. If the exterior of the transformer is bulgy or shows any burn marks, then do not test the transformer. This bulge might be a result of overheating, which is a frequent transformer failure. If the transformer seems fine visually, it is possible to proceed to test it. To accomplish this, you must ascertain the wiring of this transformer. Obtain a schematic of this circuit containing the transformer to comprehend how it is connected. The schematic will be accessible from the product documentation or on the website of the circuit maker. The electrical circuit that generates the magnetic field is going to be connected to the primary of the transformer. Another circuit which receives power from the winding will be attached to the secondary of this transformer. Now, determine the output signal filtering. You can attach capacitors and diodes into the transformer secondary to shape the AC power into DC power. This shaping and screening will be shown on the design. Now, proceed towards preparing to quantify circuit voltages. To access the circuit, you need to remove covers and panels as needed. Use a digital multimeter available at electrical supply stores to choose the voltage readings. Now, use the multimeter in AC way to assess the transformer primary by applying power to the circuit. If it measures less than 80 percent of the voltage which you anticipate, the error may be in the transformer or the circuit. In such a scenario, the primary and the input circuit should be separated. If the input power indicates the expected value, it means there is a fault in the primary. While, if the input power doesn't show the value, the fault lies in the input circuit. When there is no filtering or forming at the circuit, use the AC mode of the digital multimeter. But, if there are rectification and filtering, use the DC scale instead. It's evident that if the anticipated voltage isn't present on the secondary, then there is a fault either at the transformer or even a filtering/shaping component. To determine, you have to test the filtering and forming parts. If this testing doesn't show any problems, it becomes clear that the transformer is faulty. Electrical transformers have come to be a part of most modern industries, automation industries, textile companies, refrigeration industries, and all processing industries. No sector can be envisioned without transformers today because every business has a number of those additional machines involved, and no machine can be directly on the National grid/power distribution or work on high tension lines. Transformers are static devices that transform electrical energy from one circuit to another with changes in both voltage and current, without any change in frequency. We're a transformer manufacturer in India which offers a range of sophisticated tier transformers. The various assortment of products comprises Toroidal, health isolation, power, audio output, EI, sound line fitting, SMPS and UI transformers. Transformers are needed to be designed in line with the obligatory foreign standards. They need to meet all requirements and therefore are highly required to be protected against fire. Consequently, transformers have to be tested in a variety of ways to ensure proper operation and protection against dangers. There are several testing procedures to be followed for verifying the specifications and functionality of electrical transformers — number of tests done in the factory level. At the same time, some are carried out at the customer site. The tests at the manufacturer level comprise type tests, routine tests, and specific tests. Those in the consumer level include pre-commissioning tests, those completed on standards, and those done on a crisis basis during their service life. These tests determine the electrical, thermal and mechanical arrangement for the system where these transformers will be applied. Let us take a look at the tests done in detail, which include type tests, routine tests and Other tests.

Form test The type test confirms the simple design expectation of a transformer. These tests are carried out in a prototype unit rather than in all a lot's fabricated units. The basic design criteria of a production lot are verified through a test. This type of analysis includes the following tests -- Measurement of no-load reduction and current Measurement of insulation resistance

Routine test This test confirms the operational functionality of individual units in a production lot, testing of each unit in a lot. The tests involved in a regular review are the same as characters in a kind test, leaving out the nozzle and temperature tests.

Special test Special tests are done per the demands of clients to acquire information beneficial to them throughout the operation or maintenance of the transformer. Special tests include -- Dielectric Tests Measurement of acoustic noise level Simultaneously, with the increase or reduction in current, the voltage can be altered from high to low or low to high. Increased voltage means it's stepped up, and a decreased voltage means that it is step down. Electrical transformers work on the principle that when the primary coil is connected to current supply, a flux is setup in the core, which is connected with the coil.

What are the power transformers? Power transformers have a rating of about 20KVA, utilized in generating stations and substations at every power transmission line for stepping the voltage up or down. Power transformers in India are available as single or three phase, which you can get at prices and the highest quality. Power transformers are disconnected during light load periods and are used during heavy load periods. That is why they are intended to have leakage resistance that is greater and maximum efficacy at full load. Particular important facts are regular to any transformer -- At no load, the key applied voltage is balanced with the secondary in a perfect transformer. The induced electromagnetic force in the secondary winding of a transformer depends on the frequency, flux, and several turns in the secondary. The magnitude of flux in a transformer is the same at all levels.

How are transformers tested? Every transformer must be tested before usage. Every manufacturer needs to check their transformers before providing them to its clients. We always offer the most excellent power transformers in India which are tested after being manufactured. Two types of tests must be performed on a transformer -- open circuit test and closed circuit test -- This test can determine constants or the parameter of the transformer, efficiency, and regulation. open circuit test To perform this test, winding with voltage is linked to the primary with an ammeter. A wattmeter is connected to measure power at no load. The secondary winding is kept open. This set up will create flux from the core, leading to iron declines, which is displayed on the wattmeter. closed circuit test The secondary is shorted. Voltage at a lower level is introduced in the primary. Voltage is increased gradually until full load current flows. This creates a comparatively smaller flux, which is the reason why the core losses could be neglected. The wattmeter employed in this test indicates the entire copper losses.